Double-screw Screw Design and Granules Application PP/PE Plastic material compounding Pelletizing Machine

Basisinformation

Modell: TSE-75B, TSE-75B

Produktbeschreibung

Double-screw Screw Design and Granules Application PP/PE Plastic Material Pelletizing Machine

1.Application

TSE plastic pelletizing machine is able to process materials as follow:

- filling and modification:PE,PP,EVA+caco3;ABS,PC,PS+aluminum hydroxide,magnesium hydroxide,antimony oxide

- general and fibre color masterbatch:PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary;PE,EVA,ABS+carbon black machine pellets.

- blending modification(rubber&plastic blending ,plastic alloy) PE,PP,PS+SBS;PA+EPDM;PP+NBR;PP+PE,etc.

- functional masterbatch:PE,PP,PS+starch: de-composing machine pellets.

- glass fibre or carbon reinforcement:PP,PBT,ABS,AS,PA,PC,POM,PPS,PET+long fires,small fibres,carbon fibres,crystals and so on,etc.

- various cable material :HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP etc.

- handling after dewatering:polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene,etc

- powder coating and special material : polyester,ring oxide,lactide,polyurethane,acrylate,etc.

2.Features of pelletizer

(1) Barrel

- euro-style rectangle barrl, reflux refrigeration channel is optimized and disposed,which makes temperature difference in D areas smaller.

- innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of heater.

- the material is used high quality nitrided steel ,corrosion proof or antifriction with correspounding process.

(2) screw

- the screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment , which is possessed with high corrosion-resistat and high functions

(3)metering feeders

- various metering feeders --- single screw ,twin screw ,hollow screw,forced-feeding, side- feeding.

(4) new-style gear transmission system

- new-style project of parallel three-axises driving makes the conve axis,convey

- chain,decelerate and torque get together ,which keep it compact ,and the key bearings are imported

- soakage and spraying lubriation integrate smoothly

- technics,strengthening of tooth face,so they can ensure high torque,high precision and low noise

- the selecte material of drive components is dainty,including super intention alloy cementiteing steel,cementiting and grinding.

(5) electrical control cabinet

- frame structure control cabinet

- imported electrical elements

- imported temperature control system

- imported driving system

- interlock and multi-protection

- adopting imported PLC(OMRON or SIMES) to achieve optimized process control. stronger function,steady performance and much higher accuracy.

- it can be also accomplished full-set link-lock protection,trouble safeguard,fault alarm cluing and so on.

- operation interface on touching screen is visual and marked ,which is brief and easy to use.

(6) pelletizing system

- various modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelletizing

3.Parameter table

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Motor Power P(kw) | Screw Torque T(N.m) | Torque Rating | Output Q(kg/h) | |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 4.8 | ||

| 350-550 | ||||||||

4.our production line

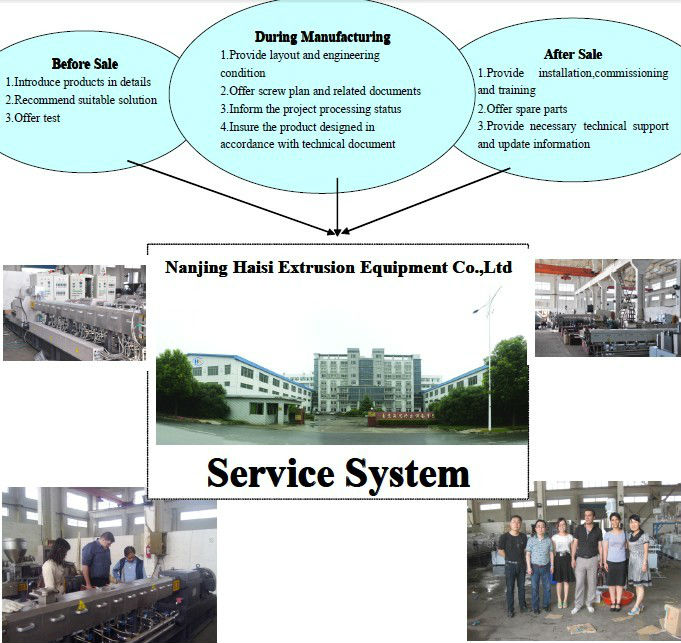

5.Service system

6.Our customers at overseas

our machines have gained wide acceptance at overseas because of high quality and competitive price and our good serivce,such as Germany, Canada, Britain, Middle east , Mexico, India and so on

Produktgruppe : mitrotierender Doppelschneckenextruder > Pelletisierender Doppelschneckenextruder

Premium Related Products