PP/PE/PVC plastic masterbatch machinery

Basisinformation

Modell: TSE-65B, TSE-65B

Produktbeschreibung

Specifications

PP/PE/PVC plastic masterbatch machinery1.model: TSE-65B

2.CE&ISO9001

3.PP/PE/PVC/ABS

4.Manufacturer

PP/PE/PVC plastic masterbatch machinery

1.Application

TSE PP/PE/PVC plastic masterbatch machinery is able to process materials as follow:

Compounds : PE,PP,PS+SBS;PA+EPDM;PP+NBR;EVA+Silicon rubber,etc.

PE,PA,PC, CEP+ABS( alloy); PBT+PET; PP+PE,etc. PE,PP,ABS,AS,PA,EVA,PET

+ long fibers, small fibers; carbonfibers, crystals and so on, etc.

PE,PP,EVA etc+aluminum hydroxide,magnesium hydroxide,antimony oxide.

PP,PA,ABS+ferrous powder, sulphuric powder, ceramic powder

Additives compounds: PP, PA,ABS,PBT etc+antiburning agent and other auxiliary agents:combustion- ---- supporting machine pellets.

PE,PP,PS etc+starch: de-composing machine pellets

Filling masterbatch: PE/PP/EVA,etc +Caco3,Talc,Tio2,Carbon black ,etc

2.Features

(1) Special screw combinations according to different materials

The screw elements and kneading blocks are designed ,by precise processed,agile combination ,with interchangeability,high shear which can fulfill efficient self-cleaning,transmission,compounding,pressure-forming,etc.the screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment, which is possessed with high corrosion-resistant and high functions

(2)metering feeders

---.various metering feeders --- single screw ,twin screw ,hollow screw,forced-feeding, side- feeding.

side feeder

liquid injection

Screw loader

Lose-in weight feeder

(3) pelletizing system

---.various modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelletizing

strand pelletizing line

Water ring pelletizing line

Air cooling pelletizing line

under water pelletizing line

(4)Parameter table of plastic pellet machinery

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Motor Power P(kw) | Screw Torque T(N.m) | Torque Rating | Output Q(kg/h) | |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 | |

3.Certificate

4.our processing center

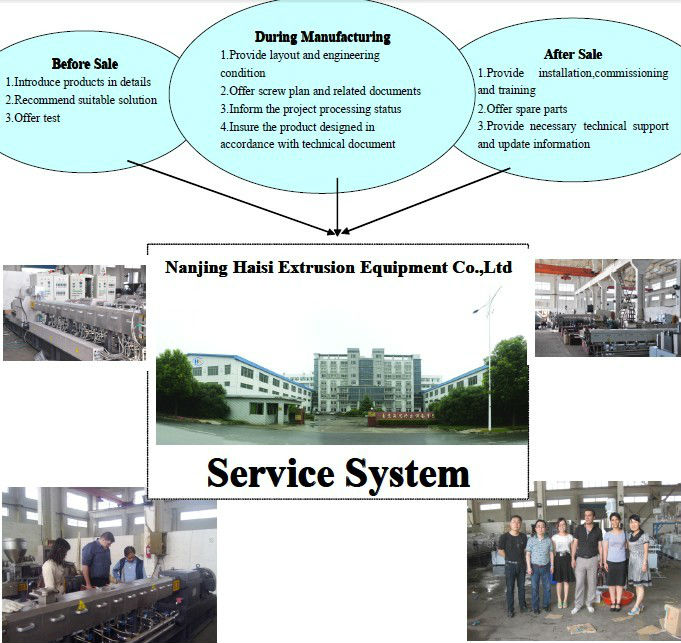

5.Service system

6.Our customers

Produktgruppe : mitrotierender Doppelschneckenextruder > PVC-Extrudermaschine

Premium Related Products