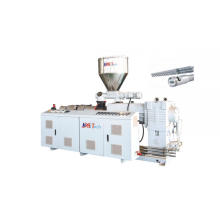

PVC granule making machine

Basisinformation

Modell: SHJ75

Produktbeschreibung

Specifications

PVC granule making machine1.High speed steel screw

2.50~1500kg/h

3.easy operation

4.CE;ISO9001

underwater pelletizing system for plastic

under water pelletizing

HS SHJ-75 twin-screw co-rotating extruder Underwater cutting / pelletizing system

Characteristics:

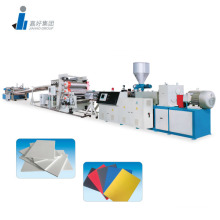

1, Euro-style rectangle barrel with reflux refrigeration channel

2, Various modes of pelletizing ,such as water-cooling strand ,air-cooling,water-ring pelletizing

3, Screw elements and kneading blocks are made of 38CrMoALA or W6Mo5Cr4V2.

4,Feeding styles are of varieties: single screw, twin screw ,hollow screw, forced-feeding,side-feeding,liquid-adding system

5,PLC, PCC or electric control system can be chosen.

Applications:

Pellets made by underwater cutting Comparing to other cutting system: The first line: Water strand cutting( left) , Air-cooling die surface cutting( right)

The second line: Underwater cuttting system

Plastic filling and modification,

General and fibre color masterbatch,

Blending modification(rubber & plastic blending , plastic alloy),

Functional masterbatch,

Various cable material,

Reactive extrusion,

Handling after venting and dewatering ,

Special material,

Powder coating

Underwater Cooling system

Technical data of TSE twin screw extruder eva tpr pelletizing machine for plastic

| Mode |

Diameter (mm) |

L/D |

Screw rotary speed (r/min) |

Motor power(kw) | Torque(N.m) | Capacity(kg/h) |

| TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 1-10 |

| TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5-30 |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 5-40 |

| TSE-40A | 41 | 32-52 | 600 | 15 | 119 | 65-110 |

| TSE-40B | 41 | 32-52 | 400 | 22 | 263 | 90-150 |

| TSE-52B | 51.5 | 32-64 | 600 | 75 | 597 | 225-250 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-300 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-550 |

| TSE-75D | 71 | 32-64 | 600 | 220-250 | 1990 | 500-1000 |

| TSE-95A | 93 | 32-64 | 500 | 250 | 2387 | 600-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 800-1200 |

| TSE-135 | 133 | 32-64 | 500 | 750 | 7162 | 1500-2250 |

CE SIO9001 TUV Certification

Good service engineers can speak english for machine errection in the world.

Develivery for customer

Contact person : Mr.Leo

Skype(Leo.nanjing)

+86 18251933105

Produktgruppe : mitrotierender Doppelschneckenextruder > PVC-Extrudermaschine

Premium Related Products