Polyethylene Extruder/Extrusion In Plastic Bottle Recycling Machine

Basisinformation

Modell: TSE-95B

Produktbeschreibung

ployethylenen extruder/ plastic bottle recycling machine /plastic extrusion

1.parameter

| Mode | Diameter | L/D | Screw Speed | Screw Torque | Motor Power | Capacity | Weight | ||||

| TSE-20 | 22mm | 32-44 | 600r/min | 43N.m | 5.5kw | 0.5-10kg/h | 1000kg | ||||

| TSE-30A | 31mm | 32-48 | 500r/min | 105N.m | 11kw | 5-30kg/h | 1500kg | ||||

| TSE-30B | 31mm | 600r/min | 119N.m | 15kw | 5-40kg/h | 1500kg | |||||

| TSE-35A/B | 35.6mm | 32-52 | 600r/min | 119N.m | 15-22kw | 20-60kg/h | |||||

| TSE-40A | 41mm | 32-64 | 400r/min | 263N.m | 22kw | 65-110kg/h | 3000kg | ||||

| TSE-40B | 41mm | 32-52 | 600r/min | 239N.m | 30kw | 90-150kg/h | 3000kg | ||||

| TSE-50A/B | 50.5mm | 32-52 | 500r/min | 430N.m | 45-55kw | 135-270kg/h | 3000kg | ||||

| TSE-65A | 62.4mm | 32-52 | 400r/min | 895N.m | 75kw | 180-250kg/h | 4000kg | ||||

| TSE-65A | 62.4mm | 32-52 | 500r/min | 716N.m | 75kw | 180-270kg/h | 4000kg | ||||

| TSE-65B | 62.4mm | 32-64 | 600r/min | 716N.m | 90kw | 200-300kg/h | 4000kg | ||||

| TSE-65C | 62.4mm | 32-64 | 600r/min | 875N.m | 110kw | 220-350kg/h | 4000kg | ||||

| TSE-75A | 71mm | 32-56 | 400r/min | 1074N.m | 90kw | 250-350kg/h | 4000kg | ||||

| TSE-75A | 71mm | 500r/min | 1050N.m | 110kw | 300-420kg/h | 4000kg | |||||

| TSE-75B | 71mm | 32-64 | 600r/min | 1050N.m | 132kw | 350-550kg/h | 4000kg | ||||

| TSE-75C | 62.4mm | 32-64 | 600r/min | 1273N.m | 160kw | 400-600kg/h | 4000kg | ||||

| TSE-75D | 71mm | 32-64 | 600r/min | 1990N.m | 200-250kw | 500-1000kg/h | 4000kg | ||||

| TSE-95A | 93mm | 32-64 | 500r/min | 2387N.m | 250kw | 600-1000kg/h | 4000kg | ||||

| TSE-95B | 93mm | 32-64 | 600r/min | 2506N.m | 315kw | 800-1200kg/h | 4000kg | ||||

| TSE-135A | 93mm | 32-64 | 500r/min | 7162N.m | 750kw | 1500-2250kg/h | 4000kg | ||||

2.characteristics

1. Nanjing Haisi TSE-95B Twin screw extruder for pelletizing use innovated design of heater tightened style,it insures high efficiency of heat transfer and high longevity of heater.

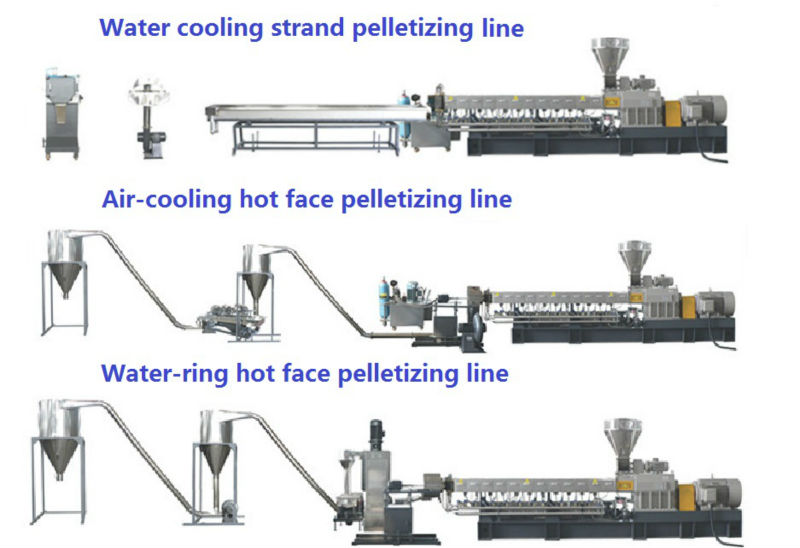

2. Nanjing Haisi Twin Screw Extruder for plastic has Various modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelletizing etc.

3.The screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment ,which is possessed with high corrosion-resistant and high functions

4.The screw configuration,barrel setup,L/D or mode of feeding and venting,screen changing,way of granulating,and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.

5.TSE-95B plastic granulator has new-style gear transmission system:

*new-style project of parallel three-axises driving makes the conveyaxis,convey

*chain,decelerate and torque get together,which keep it compact and the key bearings are imported

*the computer designs to optimize gear parameters and strengthen safe overmeasure

*the selected material of drive components is dainty.Including super intention,alloy cementiteing steel,cementiting and grinding

*technics,strengthening of tooth face.So they can ensure high torque,high precision and low noise

*soakage and spraying lubriation integrate smoothly

3. Representative Masterials

Mixing nature-changing:

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA+silicon rubber;

PE,PA,PC,CEP+ABS(alloy),PBT+PET,PP+PE

Filling nature-changing:

PE,PP,EVA,Calcium carbonate,talcum powder,titanic powder;

ABS,PC,PS,Aluminum hydroxide,magnesium hydroxide,antimony oxide;

PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder

Functional machine pellets:

PP,PA,ABS,PBT+anti-burning agent and other auxiliary agents:combustion-supporting machine pellets;

PS+starch:de-composing machine pellets,PE+fog-preventing dipper,stabilizer:dual-prevention machine pellets;PE,EVA,ABS+carbon black:black machine pellets

Colored machine pellets:

PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary

Intensified glass fibres and carboon fibres:

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET+long fires,small fibres,crystals

Various cables:

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP,Lnsulating cables;

PE peroxide silicon

special materials:

EVA heat-melting glue,polyurethane,fluorion rubber

Reaction extruding:

Polyamide condensate,polyamide melting polymerization,polyethene-adding

Exhausting and volatilization:

Polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene

Powder paint:

Polyester,ring oxide,lactide,polyurethane,acrylate

If you have any questions,please don't hesitate to contact me or send an enquiry to me!

Produktgruppe : mitrotierender Doppelschneckenextruder > Recycling-Extrusionsmaschine

Premium Related Products