Carbon black masterbatch extrusion machine equipment

Basisinformation

Modell: TSE-75B / TSE-75 C

Produktbeschreibung

Carbon black masterbatch extrusion machine equipment

Dear friend, welcome to Haisi!

Customized according to your requirement

Details:

1) Screw diameter : 71mm. L/D= 36:1/40:1/44:1/48:1

2)Main drive motor :AC 132kw,speed regulated by ABB transducer inported from switzerlad

3)Screw rotary speed:50~800rpm

4)Screw shaft is made of high-strength alloy 40CrNiMoA.

5)Lenght of each barrel is 290mm,totally 9 pieces of barrels

6)The 1st barrel is the main feeding vent,the 5th is for degassing,8th is vacuum section,and the others are closed barrels.

7)Casting copper heaters for 2.3th barrels.The others are equipped with casting aluminum heaters,All heating power:~50 kw

The extruder figure:

Feeding Degassing Vacuum

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

Four hinge style die section |

8)Reducing and distributing gearbox:

The gearbox reduces the motor speed to the speed of the screw shafts and distributes it to the 2 output shafts,

this gearbox output torque can reach 4.8T/A3

The gearbox consists of:

l Involute gear teeth couplings between the output shaft and screw shafts

l Integrated thrust bearing assembly,radial bearings of the output axis are NSK products

l Bottom part of casing designed as oil sump

| Mode |

Diameter (mm) |

L/D |

Screw rotary speed (r/min) |

Motor power(kw) | Torque(N.m) | Capacity(kg/h) |

| TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 1-10 |

| TSE-30A | 31 | 32-48 | 500 | 11 | 105 | 5-30 |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 5-40 |

| TSE-40A | 41 | 32-52 | 600 | 15 | 119 | 65-110 |

| TSE-40B | 41 | 32-52 | 400 | 22 | 263 | 90-150 |

| TSE-52B | 51.5 | 32-64 | 600 | 75 | 597 | 225-250 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-300 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-550 |

| TSE-75D | 71 | 32-64 | 600 | 220-250 | 1990 | 500-1000 |

| TSE-95A | 93 | 32-64 | 500 | 250 | 2387 | 600-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 800-1200 |

| TSE-135 | 133 | 32-64 | 500 | 750 | 7162 | 1500-2250 |

Other applications:

1, Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

2, Polymer blending:blending of PC/ABS, PA/ABS, CPE/ABS, PP/EPDM, PA/EPDM, PP/SBS,etc.

3, Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or EVA, etc.

4, Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE; radiation-crosslinkable compounds, optical fibre protection compounds, heat-shrinkable polymer compounds.

5, Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes, tobacco filter compounds, etc.

6, High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high concentration of pigments and other processing aids.

7, Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame retardants and other additives.

Characteristics:

1, New high speed and torque gear box ,type B. Key bearings of NSK products.

2, Euro-style barrels are made of high quality steel with bimetallic liners, whose refux refrigeration channel makes temperature difference in C areas smaller.

3, Screw elements and kneading blocks are designed accurately by precise process, agile combination,and interchangeability, to fulfill efficient self-cleaning, transmission , compounding and pressure built-up.

4, Water cooling strand pelletizing system insures high granulating efficiency.

Protection measure and cooling method:

1. Torque of each screw reaches 800N.m~1400N.m

2. Linkage protection of motor adopts high quality nylon pin to make sure of safety and efficiency.

3. Side tubes of water-cooling system are of high quality copper material.

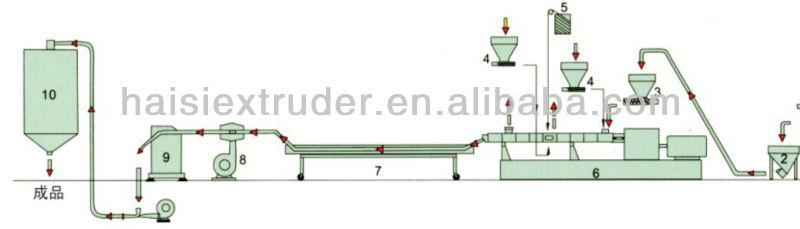

2. Loader 3. Main feeder 4. Side feeder( for short fiber) 5. Long glass fiber 6. Twin screw extruder 7. Water trough 8. Air knife 9. Pelletizer 10. Product hopper

Besides the twin screw extruder, Haisi supplies all the auxiliary machines and spare parts.

Ce and ISO9001 Certificates:

Production flow:

Auxiliary machines:

Packaging for exports:

Call me to talk more details. Skype(ryan1990427)

Produktgruppe : mitrotierender Doppelschneckenextruder > SHJ Doppelschneckenextruder