Lab use high accuracy mini plastic extruder price

Basisinformation

Modell: TSE-20, TSE-20

Produktbeschreibung

Dear Friend , welcome to Nanjing Haisi Extrusion Equipment Co.,Ltd , We are manufacturer of twin screw extruder, single screw extruder, pelletizing lines.

Lab use high accuracy mini plastic extruder price

1.Application

TSE mini extruder line is able to process materials as follow:

---filling and modification

---general and fibre color masterbatch

---blending modification(rubber&plastic blending ,plastic alloy)

---functional masterbatch

---glass fibre or carbon reinforcement

---various cable material

---handling after dewatering

---powder coating and special material

2.Features

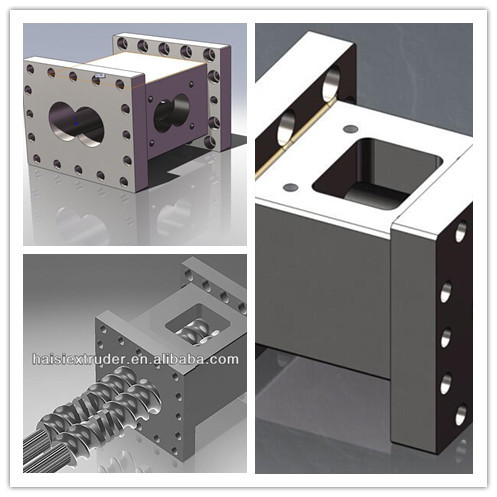

(1) Barrel

---.euro-style rectangle barrl, reflux refrigeration channel is optimized and disposed,which makes temperature difference in D areas smaller.

---.innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of heater.

---.the material is used high quality nitrided steel ,corrosion proof or antifriction with correspounding process.

(2) screw

---.the screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment , which is possessed with high corrosion-resistat and high functions

(3)metering feeders

---.various metering feeders --- single screw ,twin screw ,hollow screw,forced-feeding, side- feeding.

(4) new-style gear transmission system

---new-style project of parallel three-axises driving makes the conve axis,convey

---chain,decelerate and torque get together ,which keep it compact ,and the key bearings are imported

---soakage and spraying lubriation integrate smoothly

---technics,strengthening of tooth face,so they can ensure high torque,high precision and low noise

---the selecte material of drive components is dainty,including super intention alloy cementiteing steel,cementiting and grinding.

(5) pelletizing system

---.various modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelletizing

3.Parameter table

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Motor Power P(kw) | Screw Torque T(N.m) | Torque Rating | Output Q(kg/h) | |

| SHJ-20 | 22 | 32-44 | 600 | 5.5 | 43 | 7.5 | 0.5-10 | |

4.Certificate

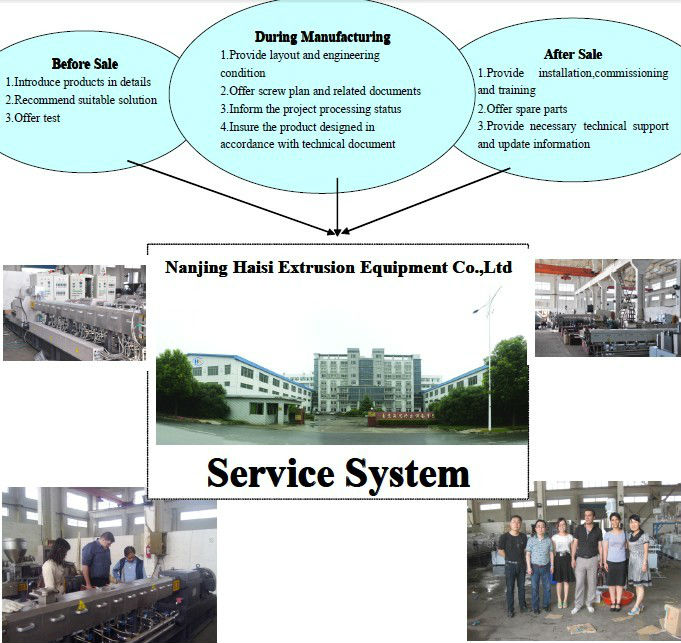

5.Service system

other pelletizing machine

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Main Power (kw) | Torque(N.m) | T/N3 | Output Q(kg/h) |

| TSE-35A/B | 35.6 | 32-52 | 600 | 15-22 | 119 | 4.4 | 20-60 |

| TSE-40A | 41 | 32-64 | 400 | 22 | 263 | 6.4 | 65-110 |

| TSE-40B | 41 | 32-52 | 600 | 30 | 239 | 5.8 | 90-150 |

| TSE-50A/B | 50.5 | 32-52 | 500 | 45-55 | 430 | 5.4 | 135-270 |

| TSE-65A | 62.4 | 32-52 | 400 | 75 | 895 | 6.3 | 180-250 |

| 500 | 75 | 716 | 5.1 | 180-270 | |||

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 5.1 | 200-300 |

| TSE-65C | 62.4 | 32-64 | 600 | 110 | 875 | 6.2 | 220-350 |

| TSE-75A | 71 | 32-56 | 400 | 90 | 1074 | 4.9 | 250-350 |

| 500 | 110 | 1050 | 4.8 | 300-420 | |||

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 |

| TSE-75C | 62.4 | 32-64 | 600 | 160 | 1273 | 5.8 | 400-600 |

| TSE-75D | 71 | 32-64 | 600 | 200-250 | 1990 | 9.2 | 500-1000 |

| TSE-95A | 93 | 32-64 | 500 | 250 | 2387 | 5.0 | 600-1000 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2506 | 5.3 | 800-1200 |

Produktgruppe : mitrotierender Doppelschneckenextruder > TSE Doppelschneckenextruder

Premium Related Products